European Defence Fund Call: EDF-2022-LS-RA-SMERO

(Non-thematic research actions targeting disruptive technologies for defence)

Proposal: Rapidly deployable military IoT and sensor network (RADEMIS)

Information superiority has always been regarded as key in warfare. In an increasingly digitised world with an ever “smarter” battlefield and short innovation cycles, reaching and keeping information superiority becomes more and more complex and challenging. The challenge to combine conventional and modern/hybrid elements in warfighting is acknowledged by the EU- and NATO-member states and has become even more crucial since Russia’s attack on Ukraine in February 2022.

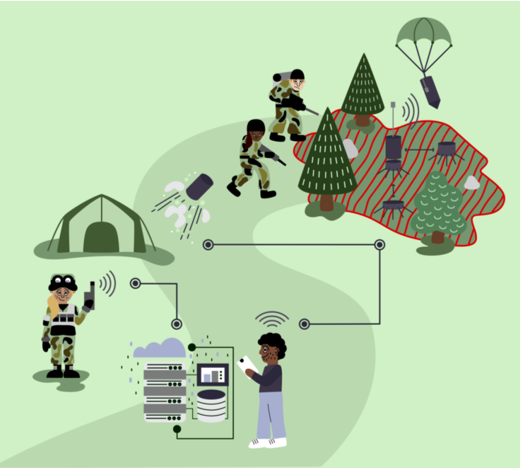

Aiming at contributing to information superiority at the “last mile” on the battlefield, RADEMIS targets rapid deployment of sensor, effector and communication devices into terrain inaccessible by other means (see Figure 1 for a system overview of RADEMIS) such as territories occupied by hostile forces or territories which are very remote or even contaminated.

While fast and precise sensor deployment is straightforward in the civilian domain, military missions typically pose additional constraints on the deployment and the deployed devices. Within the outlined project, we focus on deployment by means of rocket technology, however, we elaborate on other military relevant options for delivery. Despite the commercial availability of multiple electronic devices, the military use confronts them with three substantial and largely unsolved issues, in contrast to civilian applications: a) robustness, b) deployment and c) camouflaged/concealed operation behind enemy lines. RADEMIS addresses all three challenges in an innovative way, setting up a highly versatile system with multi-mission capabilities.

To a large extent, RADEMIS combines existing technologies such as

▪ Sensor network capabilities

▪ High-g launch systems like mortars, howitzer, rockets, missiles etc.

▪ Hardening electronics

▪ Modern data management

▪ Remote controllability

▪ Camouflage, decoy and spoofing options

in an innovative manner by designing generic mechanical, electronical and software interfaces to operate an arbitrary composition of devices seamlessly.

After deploying the carrier vessel, the system allows to elevate and rotate the payload by a patented mast system in combination with a pan-tilt unit (PTU), if required by the situation or the environment. The additional elevation/positioning provides an operational advantage for sensors, effectors and antennas likewise. RADEMIS focusses on solutions with a low signature like passive sensor systems and active electronic devices (spoofer, jammer, decoy, laser) functioning as effectors.

The project addresses the full scale of military operational and technical requirements such as robustness, speed of intervention, interoperability, mobility, availability, security and full coverage of the targeted domain by sensor readings. Due to its modular setup, the targeted devices will combine a high versatility (multi-mission capability) with easy handling by the end-users and a range of potential applications also in the civil domain (contaminated areas, wildfires).

The designed solution offers tactical, operational and technological advantages to the European armed forces. The RADEMIS system complements the portfolio of technological means to conduct reconnaissance missions by bringing civilian technology into the military domain. With its focus on remote controllability, RADEMIS helps to minimise the risk for the end-user.

RADEMIS

RADEMIS System overview. RADEMIS deploys devices rapidly into the target domain (indicated by red striped overlay) by launching methods involving high-g forces. Upon deployment, the mast system provides additional elevation supporting operation and communication. To avoid data congestion, basic data fusion happens in the field (learning in the field), but RADEMIS reports relevant information via an C4ISR1 system to the decision authorities (headquarter depicted as tent).

Consortium

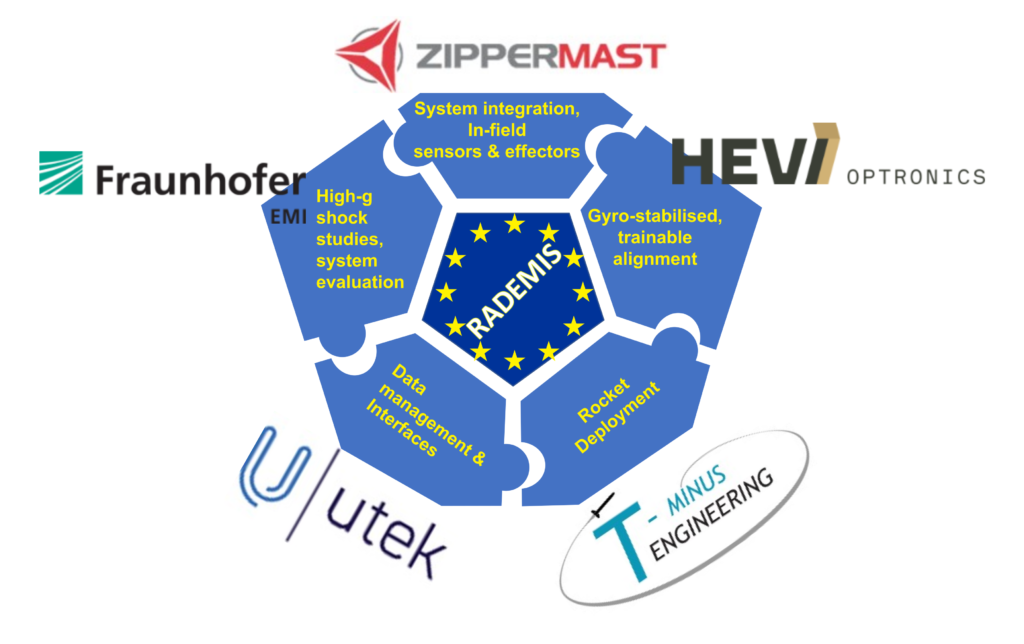

The size of the RADEMIS consortium was chosen to match the objectives and workload, but remain lean enough to be able to act agile and flexible. The five beneficiaries located in four different Member States of the European Union (compare Figure 6 on page 26) share a well-balanced workload. Coordinated by the SME Zippermast GmbH [DE], the RO Fraunhofer EMI [DE] and the three further SMEs Unmanned Teknologies Applications S.L. [ES], HEVI Optronics OÜ [EE] and T-Minus Engineering [NL], compile the following expertise:

Zippermast GmbH

(ZM)

Zippermast is an innovative SME based in Bad Reichenhall, Germany, which has established itself as a partner in the fields of security and defence as well as security-related industry since 2014. With a focus on defence technology, Zippermast supports armed forces in integrating sensors and effectors in preparing for the battlefield of the future. Its key technologies meet the individual requirements of modern armed forces in terms of reliability, modularity, interoperability and flexibility. Zippermast strives to provide solutions that contribute to responsiveness and superiority in modern battlefield scenarios. The focus is on developing systems that directly support forces in harsh operational conditions and provide a bridging function between tactical and operational levels.

T-Minus Engineering

(TME)

T-Minus Engineering B.V. is a Dutch SME founded in 2011 at Delft and has steadily grown to employ a full time equivalent (FTE) of 10 persons. We aim at growing the company further to 20 FTE by 2024. TME focuses on the design of rocket systems and is unique in the way that it works on rocket systems from concept to operations. The conceptual stage includes simulations relevant for structural and operational safety of the rocket system.Over the past 10 years TME has launched over 100 rockets, including space capable rockets from Australia (2020), Norway (2021) and the UK (2022). TME produces its own rocket motors ranging from 100 g spin motors to 100 kg rockets motors. The largest rocket motors carry payloads of 20 kg to 200 km apogee. Nearly all the engineering work and production on the propellant, motors, structures, ejection systems, control systems and electronics is performed inhouse.

Unmanned Teknologies Applications S.L. (UTEK)

UTEK is a Spanish SME based in Madrid and specialised in the development of unmanned systems as well as electronics and software design. It has experience in defence solutions in maritime, aerial and ground domain. UTEK’s solutions are focused on high reliability and advanced performances to meet the most demanding user requirements. The company has also a strong background in European Defence Projects (EDIDP) and has a close contact with the Spanish Ministry of Defence.

HEVI Optronics

(HVO)

HEVI Optronics OÜ is an Estonian SME based in Väänä, designing and developing precision-engineered electro-optical sensor systems for commercial and defence applications. We are integrating the latest sensor technologies and video enhancement algorithms into a modular system architecture. We provide stand-alone and turn-key solutions for Air, Land, Sea and Surveillance markets and offer relevant support and system integration services.

Fraunhofer Ernst-Mach Institut

(Fraunhofer EMI)

Fraunhofer has been performing applied R&D since its foundation in 1949 as non-profit organisation in Germany. The Fraunhofer Institute for High-Speed Dynamics, Ernst-Mach-Institute (EMI), Freiburg, has been an internationally renowned institute for defence-related research in Germany since 1959, with specific expertise in high-speed measurement techniques, acceleration and shock testing, ballistics, and explosion mechanics. It’s close ties with the German Ministry of Defence through institutional basic research funding and projects as well as contributions to numerous EU framework and Horizon programs highlight the expertise of the EMI.

The facilities at Efringen-Kirchen include equipment most suitable for studying electronic parts in the high-g-regime: pressurised air gun to generate high loads and an autonomous data recorder “g-rec” to monitor forces during a shock. Complementary to the laboratory facilities, the institute features experience in numerical analysis and shock hardening electronics.